Quality Praised by 300+ Japanese Pharmaceutical Companies

Notice of Company Name Change

Effective April 1, 2024, Nitto Kinzoku Kogyo CO., Ltd has changed its name to MONOVATE Co., Ltd.

MONOVATE have been manufacturing and selling stainless steel containers in Japan since 1957.

Our business range is centered on the manufacture and sale of stainless steel containers used in the pharmaceutical industry, as well as a wide range of fields including cosmetics, foods, chemicals, semiconductors and more. In addition, our main partners outside Japan are pharmaceutical companies in the United States.

Browse by Category

Simple, easy-to-use standard stainless containers

Useful when moving and transporting our containers.

Durable and reliable replacement parts

Funnel-shaped containers for easy input and storage of powders

Smooth discharge saves time and costs

Utilize jacket layer for heating and cooling

Robust pressure vessels for liquid and chemical protection

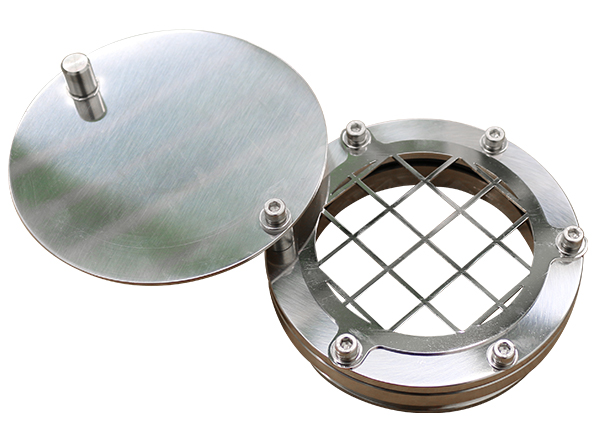

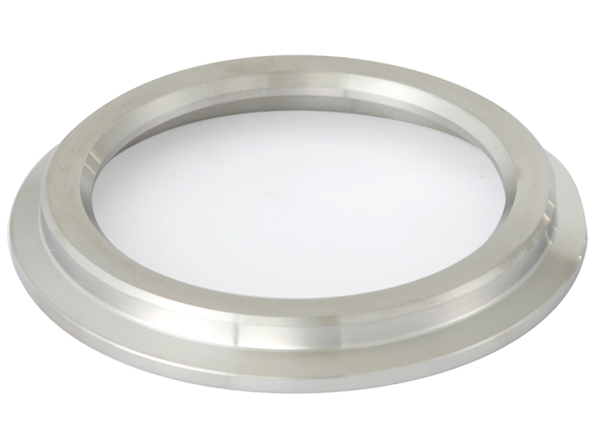

Products for container visibility and safe connections

Bottles and instruments for use in laboratories and production lines

All in one function for mixing and temperature control of materials

Agitators for uniform and efficient mixing

Diverse peripherals to optimize the work environment

Free download of 10000+ drawings

You can download free drawings for most of MONOVATE’s products.

You can check the design details in business meetings with customers or use them immediately for designing new products.

The drawings are available in PDF, DWG, and DXF formats. You can download them immediately after free membership registration.

-820x1024.jpg)

Stainless steel container for pharmaceutical industry

The containers MONOVATE produce are particularly well-received by the pharmaceutical industry. Containers used in the pharmaceutical industry in the United States and Japan are required to meet the GMP (Good Manufacturing Practice) standards of the FDA (Food and Drug Administration), with which our products are strictly compliant.

In addition, we have delivered products to all 310 pharmaceutical companies in Japan as of 2014 (with reference to the Japan Pharmaceutical Industry Data Book 2017).

We have also made great achievements with Japan’s “mega pharmacies,” Takeda Pharmaceutical Co., Ltd., Astellas Pharma and Daiichi-Sankyo, as well as generic pharmaceutical companies and health food manufacturers.

The main uses of our products are not limited to storage or transportation; our products can also be used in mixing and pressurization operations in the manufacturing process. In addition, we also have cultivating tanks for biological agents, purified sinks for tablet factories, and injection adjustment tanks. We have produced many tanks with high quality requirements.

Only one product in the world

Our greatest strength is in providing our customers with advanced customization services for stainless steel container products and in proposals for customers who need system products, using our 60 years of accumulated achievements and experience.

The minimum order quantity is, of course, “1”.

Thousands of our base products are available in our catalogue and on our homepage.

The customer can choose the suitable container for their own use, and then customize it, such as by adding more functions to the base container.

For example, we can make a product like this: the required capacity is 40l, the total height is 1500mm from the floor, the discharge port is mounted at 500mm high, a level meter is added to the body for easy observation of the interior, and casters are added to allow women to move it easily inside a pharmaceutical factory (without damaging the factory flooring).

We can propose such products, which are unique in the world, and can enhance the productivity of your company.

We have 120,000 custom-made design drawings for stainless steel containers.

This is an asset that we alone have cultivated over our 60 years of experience.

Experienced sales engineer

For example, if you want to make a bespoke stainless steel container, you might want to ask a local iron and steel factory or engineering company.

However, they may not have much practice or abundant experience.

You may need to conceive an idea, make a design drawing, order materials from scratch, and worry about the price, quality, and even the delivery date.

We possess thousands of base containers, tens of thousands of production drawings, 60 years of experience, and veteran sales engineers who can provide the right advice to the customers.

MONOVATE knows the quality that is best for you

There is no doubt that our company can better meet the needs of customers.

You don’t have to worry about the quality.

One of the most important qualities for a factory making bespoke products is a grasp of quality.

We understand the quality that you might need:

The quality required by a factory making blood products, the quality required by a factory making tablets, the culture tank required by a biotechnology company, the pressure vessel required by a semiconductor manufacturer, and the quality necessary for the intermediate storage drum for a health-care food manufacturer—we understand all the quality requirements in various areas.

This is thanks to the thousands, even tens of thousands of troubles and difficulties we have experienced over 60 years.

We have coped with these troubles and difficulties with integrity, and resolved each and every one.

Stirring tank

People have a lot of different ideas in the field of stirring.

Some argue that as long as there is a blender, anything can be easily mixed.

In fact, this is not the case.

What needs to be mixed, what to use, the operating conditions (temperature, capacity, etc.)—these problems need to be considered, and based upon their results the appropriate mixer, fan blade shape, and container must also be selected.

Further, one cannot determine if the ingredients can be mixed if stirring operation is not actually carried out.

Our company has containers and mixers of different shapes (including stirring fan blades).

In addition, the combined use of electronic control with heaters and cooling units can lead to a huge leap in productivity.

Can a company that only makes mixers do this? We can systematically provide a solution to this problem.

Tank capacity

We are skilled at making containers and systems from several milliliters to hundreds of liters, though we do not handle huge tanks holding thousands of liters.

Our products are commonly used in the pilot scale production stage, after the raw material experimental phase has been completed and before the formal production phase.

In addition, in Japan, with its advanced multi-model small-lot production, our products are also very commonly used.

For example, a company can produce potato chips with limited-edition or limited-region flavors by using our tanks with 10 to 100-liter capacity.

Variety of accessories

Other uses are too numerous to mention here, but we produce hundreds of custom-made products and systems each month.

We also have a wide variety of accessories and functional containers for these stainless steel containers.

Most of the accessories we plan and produce are only manufactured by our company, because we plan new products based on abundant custom orders from all over the world.

Some of the accessories and functional containers we produce are sold only once a year. However, in other words, “we always sell one a year.”

We have hundreds of unique products throughout the world and are ready to propose the product that you want.

Made in Japan

The main material of our tanks is stainless steel, with various methods of surface treatment available, such as PTFE coating, electrolytic polishing, buffing, etc.

The quality of the surface is the most important quality for a stainless steel tank.

We are also particular about the stainless steel raw material itself (SUS304, SUS316L).

The stainless material we use is the highest grade product manufactured in Japan.

We have BA materials (with glossy surface) in stock, which are not normally distributed on the market.

This BA material in the coil is scarce, even in Japan.

As well as focusing on the raw material quality, we also make a point of our welding technology.

The most important thing in manufacturing is to use the best material and the best technology, and avoid extra effort.

Too much effort means a decrease in quality.

Our company has the best materials and the best technicians and artisans, some of whom have over 30 years’ experience.

They are absolutely indispensable in making a good tank.

Various introduction results

Our current customers are not limited to pharmaceuticals; we serve a variety of industries including biotechnology, cosmetics, chemistry, food and semiconductors. In addition, our products are often used for the following purposes:

– Raw material storage tanks for electronic cigarettes

– Tanks used in the production of ink for ink cartridges

– Brewing vats for craft beer (hundreds of liters)

– Tanks for coating potato chips with chocolate

– Collection tanks for cooking oil

– Collection containers for powder products

– Tanks for manufacturing lipstick and mascara