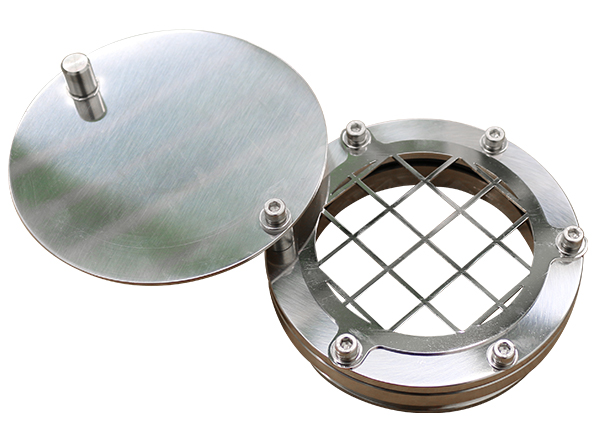

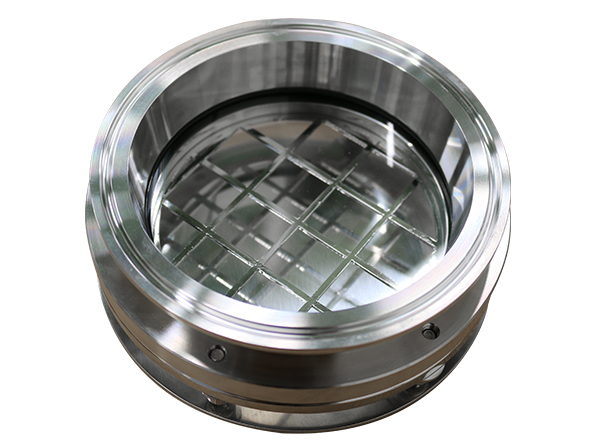

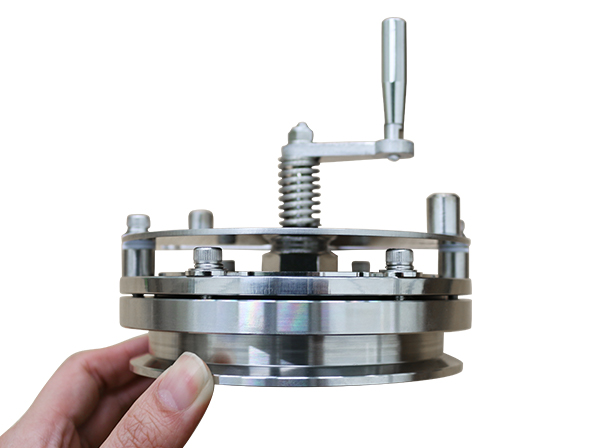

Sight Glass (Integrated) with Various Protective Net and Protective Cover

Delivery to lithium ion battery manufacturers

○This is a custom-made example of a peep window that is attached to the lid of a temporary storage tank.

・It is used by attaching to the lid of the temporary storage tank to send the positive electrode slurry of the lithium-ion secondary battery for automotive use sent from the disperser to the storage tank.

・At the request of customers, we have installed a protective net and a protective cover based on the (Integrated) [NMB] and the (Integrated) [NMBW] with wipers.

・They are used for lighting and inspection respectively.

・Since there are many nozzles attached to the lids, it is designed not to interfere with them.

・The protective net at the top of the glass window prevents the glass window from being damaged when objects fall into it, and prevents the glass window from scattering outside when it is damaged under pressure.

・The protective cover has the same effect as the protective net. If the cover is closed when the peep window is not in use, dust and other particles can be prevented from adhering to the window. The protective cover is a sliding type to prevent dropping or loss. In addition, the protective cover of the peep window with wipers is divided into two parts so as not to interfere with the wiper shaft.

Window Frame Wetted Part SUS 316 L

Window Heat-Resistant Tempered Glass

Flat Packing EPDM

Connection 4S Hi-rule

CONTROL NUMBER 1U011220FB # 37

Slant-bottom Type Container (with funnel)

*Typical Application: chemical manufacturer, etc.

○ Container for charging and filtering liquid.

- Put the liquid into the upper funnel, remove foreign substances by punching the mesh and filter it to the lower container.

- With the level meter, you can easily check the amount of liquid that has been filtered and accumulated in the lower container.

- The bottom of the container is inclined to the discharge drain so that the liquid can be discharged smoothly.

- The plate thickness is thicker than the normal single-tapered container [KTT-CTL] as reinforcement.

Capacity: 30 L

Size: φ 360 mm × Height 796 mm

Material: SUS304

Board thickness: t 1.5 mm

Finish: internal and external # 320 buffing

Others: Reinforcement board (lid, bottom of body), level gauge

Management number: 1P007816

Mixing container with square-shaped observation window (coated with fluorocarbon resin)

*Typical Application: General chemical material companies, etc.

○ The container body and the stirring blade are made by stainless steel SUS316L, which has corrosion resistance.

- You can check the stirring condition with a square-shaped observation window.

- The inner surface of the observation window has a smooth finish with no difference in the inner surface of the container.

- There is almost no residue left by the sanitary type tank ball valve.

- High-viscosity contents adhered to the wall can be removed and well-stirred by scraper attaching to the stirrer.

- The inner surface is coated by non-adhesive fluorocarbon resin for discharging the contents smoothly.

Capacity: 8L

Material: Body: SUS316L

Gasket: Silicon rubber

Square window: Pyrex

Finishing: External buffing (staining for coating process)

Inner 50 μm PFA coating

Parts Agitator: 100V

Agitation blade: SUS316L

Scraper: silicone rubber

Sanitary ball valve: SUS316L

Management number 1L001285