PCN-O : Flange Open Pressurized Container

Features

Pressure vessel with flange opening.

Straight type with the same bore and inner diameter.

○As it is an open type, it can be easily cleaned.

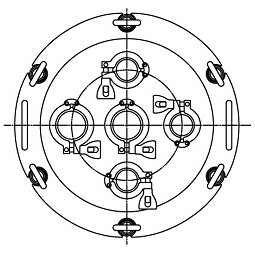

○Swing bolt type that prevents parts from falling off when opening and closing the lid.

○You can select accessories according to your use.

○As it is a build-to-order product, you can make changes to "Dimension" "Material" and customize it to suit your needs.

Price:

Product Introduction Video

Product Specifications

Container Body ... SUS 304

Handle, Hakama ... SUS 304

Lid ... SUS 304

O-Ring ... Silicon Rubber

●Surface Treatment: Inner and Outer Surface 0.2Ra

Capacity: 10 L, 20 L, 30 L, 40 L, 50 L, 80 L, 100 L, 150 L, 200 L

Contact us for other capacities.

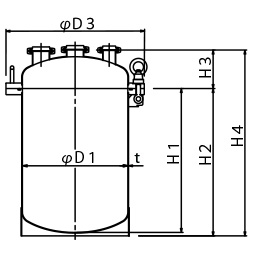

Reference Dimensional Drawing

Drawings & Certificates

Request Drawings & Certificates / Contact UsDetails & Notes

| Model | Capacity | Weight | Diameter | Flange Diameter | Internal Height | Container Height | Lid Height | Overall Height | Plate Thickness | Lid Nozzle | Working Pressure | RoHS | Lead Time |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | kg | D1 | D3 | H1 | H2 | H3 | H4 | t | Size and Quantity | Room Temperature | Days | ||

| PCN-O-10 | 10 | 21 | 259.4 | 355 | 240 | 250 | 124 | 374 | 1.5 | 1S: 4, 2S: 1 | 0~0.18MPa | Compliant | 40 |

| PCN-O-20 | 20 | 23 | 259.4 | 355 | 430 | 440 | 124 | 564 | 1.5 | 1S: 4, 2S: 1 | 0~0.18MPa | Compliant | 40 |

| PCN-O-30 | 30 | 31 | 309.5 | 406 | 440 | 450 | 112 | 562 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

| PCN-O-40 | 40 | 34 | 345.6 | 440 | 490 | 500 | 119 | 619 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

| PCN-O-50 | 50 | 42 | 396.4 | 492 | 490 | 500 | 131 | 631 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

| PCN-O-80 | 80 | 47 | 396.4 | 492 | 720 | 730 | 131 | 861 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

| PCN-O-100 | 100 | 60 | 500 | 595 | 600 | 610 | 156 | 766 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

| PCN-O-150 | 150 | 66 | 500 | 595 | 850 | 860 | 156 | 1016 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

| PCN-O-200 | 200 | 85 | 550 | 645 | 930 | 940 | 166 | 1106 | 2 | 1.5 S: 3, 2S: 2 | 0~0.18MPa | Compliant | 40 |

Available to products made of SUS316L material!

The standard material for Nitto Kinzoku is SUS304. SUS316L is a material with higher corrosion resistance than SUS304. It contains an ingredient called “molybdenum”, which is not contained in SUS304. This molybdenum makes the passive film thicker and improves the corrosion resistance. SUS316L is a low-carbon type stainless steel with a low carbon content, and is resistant to corrosion (intergranular corrosion) in the welding area where parts are connected to each other. SUS316L is generally recognized as a high-grade model of stainless steel material. It is a material that is commonly used in production sites in the pharmaceutical industry. If you are concerned about rust and corrosion resistance, we recommend you to select SUS316L. For more details, please contact us.Q&A

- QCan I change the material of the container?

- Acan. There is SUS316L.

- QI corrosion resistance of need ...

- AIt can surface treatment of the fluorine resin coating.

- QSize is not in the catalog, can I capacity?

- AWe manufacture by changing the height of the container of the near capacity.