Not just a mixer.

There are approaches that suit your purpose.

The efficiency of agitation is determined not only by the mixer or agitator blades but also by multiple

factors such as the container, valves, and processing to change the liquid flow.

With expertise in stainless steel containers and agitation, Nitto Kinzoku Kogyo can approach your

“agitation concerns” from various perspectives.

Do you havethese concerns?

- It’s troublesome to communicate with both the agitator and container manufacturers.

- You don’t know what type of agitator or container to use to achieve the desired agitation.

- You want to change the specifications for each unit according to production processes, content, or

capacity.

Nitto Kinzoku Kogyo cansolve everything.

Three strengths ofNitto

Kinzoku Kogyo

1. Combination of Mixer and Container Manufacturers

Nitto Kinzoku Kogyo is a manufacturer of stainless steel containers and mixing equipment. We have

expertise in both containers and mixers, which allows us to propose the optimal combination to

solve your problems.

2. Abundant Customization Examples

We create fully customized stainless steel container units to meet your specific needs. With our

extensive experience in custom-made products, we can offer advanced proposals based on your

requirements.

3. Ideal for Small-scale Production with a Wide Variety of Products

Our products are ideal for small-scale production with a wide variety of products, as we

manufacture them one by one with welding and custom-made processes. If you need to change the

specifications for each machine, or if you want to start with just one machine, please consider

Nitto Kinzoku Kogyo.

\ Let us know the contents and quantity to be stirred /

1. Mixer Manufacturer x Container

Manufacturer

“When the container manufacturer and mixer manufacturer are separate, we have to adjust the

opinions of each manufacturer here when stirring cannot be done well…”

To alleviate such customer burdens, Nitto Kinzoku Kogyo proposes both mixer and stainless steel

containers together.

If stirring is not working well, we can propose the optimal solution by considering not only the

mixer or stirrer but also the container’s shape, valve, and other processing comprehensively. This

is possible because we are

knowledgeable in both the mixer and container.

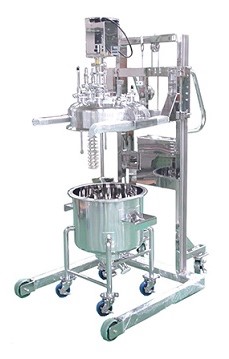

[Adopted by a Pharmaceutical Manufacturer] Jacketed Container with Pressure Control and

Magnet-Type Stirrer

– Two Stirrers Installed to Dissolve and Defoam Powder and Liquid –

Container for dissolving powder and liquid, defoaming, and then sending them to other

machines.

Water warmed by a chiller circulates in the jacket of the container, and the contents are

temperature-controlled by heating. The contents are then stirred by a total of two magnet-type stirrers installed at the top and bottom

of the container.

Then, the foam created by stirring is defoamed by pressure reduction, and the solution is

sent to other machines under pressure.

Due to the use of a tank bottom valve with a small dead

space when stirring, efficient stirring can be achieved at the discharge

outlet.

2. Extensive Customized Examples

“I want to stir high viscosity liquids.”

“I want to stir while minimizing contamination risks.”

First, please let us know your requirements. Nitto Kinzoku Kogyo manufactures completely

customized stainless steel container stirring units.

If stirring is not going well with your current equipment, please let us know your situation, and we

will analyze why stirring is not going well based on our extensive

stirring unit production examples.

Then, we will propose the best design and processing to solve your problems.

【Surfactant Manufacturer Adoption】Wax Dissolution Heater Unit

~Prevents wax discoloration and contributes to stable quality~

○Before introducing our product

They were liquefying solid wax in a cylindrical container with just a belt-wrapped

heater. However, this resulted in uneven heating, discoloration, burning, and other

quality instability problems.

○How we solved the problem

We proposed a jacket-type container that can slowly stir

and liquefy using a water bath. In addition, we adopted anchor blades to

forcibly move the wax to prevent it from adhering to the container walls.

→Prevents

discoloration and burning

3. Ideal for Small-scale Production of

Multiple Varieties

Our products are ideal for small-scale production of multiple

varieties or in prototyping stages. We

offer stirring units tailored to each production process, taking into account the contents

and existing equipment at the time.

We can modify the size according to the customer’s required size and perform additional work

to contribute

to the efficiency of production processes.

\ Punch illustrations and drawings can also be attached /

“When you want to

confirm usability before purchasing”“When you want to

actually try stirring”

We also provide demo and rental services.

If you want to try using our products before purchasing:

- You want to try stirring the actual materials to be used

- You want to confirm that stirring is not a problem

At such times, please use our pre-purchase demo and rental services.

We propose demo products based on your application, challenges to be solved, and content you want to

confirm with the demo or rental. Based on the results obtained, we will consider the optimal

specifications for you.

Confirm product specifications and get a quote here

\ We solve your problems /

For those who have decided on the

specifications, this is convenient

Inquiries by Phone or FAX

Inquiries by Phone

048-996-4221Weekdays from 9:00 a.m. to 5:00 p.m.

Inquiries by FAX

048-996-8781

24-hour reception

FAX Form is available.

Please print and use it.