A ‘Stirring Unit’ Combining

Stirrer, Stainless Container, and Valve

\ Stirring test loans are also possible

/

Inquire about this product

This usage is possible

- Mixing and dispersing of raw materials (Stirring Unit)

- Dissolving, heating, and cooling of contents (Stirring Temperature Control Unit)

- Defoaming and pressurizing foamy liquid after stirring (Stirring Pressurizing Unit)

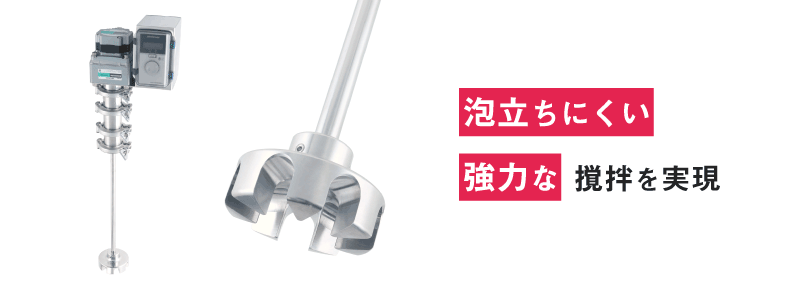

What’s Special About

Bernoulli Flow Stirring Unit?

Adopted Bernoulli

Flow

Stirrer that excels insuppressing foam during

stirring!

Equipped with “Bernoulli Flow Stirrer BEAG”, this stirrer can achieve “less foaming” and “powerful”

stirring

by generating a liquid flow in the container with a principle different from the usual stirrer (pressure

difference by centrifugal force).

It suppresses foaming by reducing air entrainment from the liquid surface.

This can help reduce the time spent on defoaming in subsequent processes, and prevent foaming and

overflow

at the liquid surface.

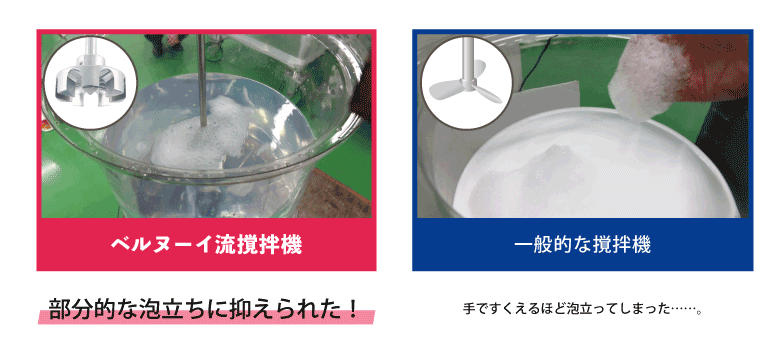

Does it really not foam? We splashed around water and detergent to see.

Compared to a general propeller-type stirrer…

The Bernoulli Flow Stirrer was able to significantly suppress

foaming.

Click here if you want to Learn More about the

detergent stirring experiment video

\ Please tell us “what purpose”, “what”, and “how much” you

want

to stir /

Three Types of Units Available for Different Purposes

If the goal is “mixing,

homogenizing, preventing sedimentation”, then choose “Stirring Unit”

A simple unit that specializes in stirring only, without temperature or pressure control. By

limiting

its functions, it can be introduced at a low cost.

You can choose from two types of container shapes

“Mirror plate type container” type that excels

in

stirring efficiency

“Single taper type container” type that

promotes

smooth horizontal discharge

\ You can also attach drawings or diagrams /

If the purpose is “dissolution, heat transfer (heating or cooling)”, choose “Stirring

Temperature

Control Unit”

This unit can heat or cool (insulate or refrigerate) the contents. The container is a double tank

structure, and the temperature of the contents is controlled by circulating hot water or cold

water

in the outer tank.

You can choose from two types of container shapes

“Mirror plate type container” type that excels

in

stirring efficiency

Bernoulli

Flow

Stirring Temperature Control Unit DTHB-J Type

* A separate circulation system is required. Please contact

us

for more details.

“Single taper type container” type that

promotes

smooth horizontal discharge

\ You can also attach drawings or diagrams /

If the purpose is “pressure

transport after stirring, promoting reaction”, choose “Stirring Pressurized Unit”

A unit with a pressure-resistant container set. It is suitable for stirring processes that do not

want to be exposed to air or that include a degassing process.

You can choose from two types of container shapes

“Flange Open” type with lid secured by swing

bolts

Bernoulli

Stirring Pressure Unit PCN-O-J-L type

Non-jacketed type

also

available.

“Ferrule Open” type with lid secured by clamp

band

Bernoulli

Stirring Pressure Unit PCN-F-J-L type

Non-jacketed type

also

available.

\ We can also attach punch illustrations and drawings /

“I want to know the detailed specifications and price!” “Can it be used this

way?”

For inquiries and requests for quotes, click here

\ We will solve your problems /

Phone Inquiries

048-996-4221Weekdays 9AM – 5PM

FAX Inquiries

048-996-8781

24/7 reception

We have prepared a FAX Form.

Please print and use it.