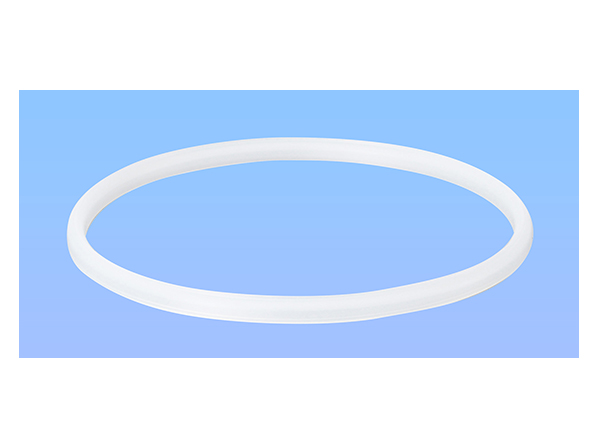

PQA : A-Type Silicon Packing

Features

Packing exclusively for CTH/CTB type airtight containers.

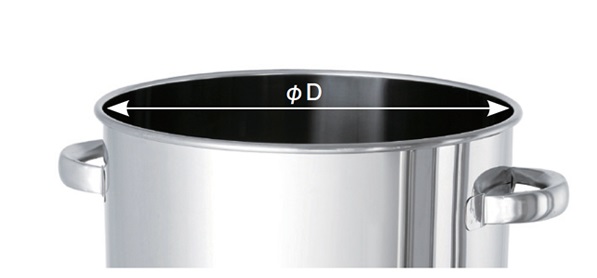

○Set by covering the edge of the container.

○Easy to put on and take off, convenient for cleaning.

○Conforms to FDA 177.2600.

Price:

Product Specifications

Material: Silicon Rubber (Food Sanitation Law, FDA 177.2600 compliant products)

Color: Milky White

●We have colored packing.

・Type A Color Silicon Packing (Red/Blue/Green): [PQA-RE/BL/GR]

●Different materials are available.

・FKM (Fluorine Rubber) Type: [PFA]

・EPDM (ethylene-propylene rubber) type: [PEA]

・NBR (nitrile rubber) type: [PNA]

・CR (chloroprene rubber) type: [PCA]

*The above four colors are black.

For other materials, please contact us.

・PTFE (resin) packing is also available. Type: [PPA]

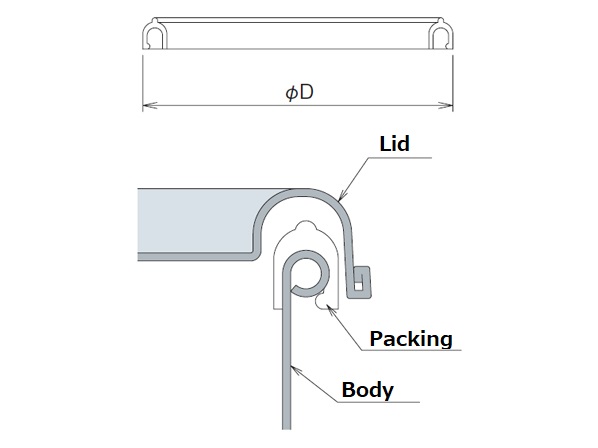

Reference Dimensional Drawing

Drawings & Certificates

Request Drawings & Certificates / Contact UsModel # List

| Model | Weight | Applicable Container | PackingOuter Diameter | Lead Time |

|---|---|---|---|---|

| kg | Diameter | D | Days | |

| PQA-18 | 0.03 | 180 | 194 | 2 |

| PQA-21 | 0.06 | 210 | 225 | 2 |

| PQA-24 | 0.08 | 240 | 260 | 2 |

| PQA-27 | 0.08 | 270 | 285 | 2 |

| PQA-30 | 0.1 | 300 | 321 | 2 |

| PQA-33 | 0.12 | 330 | 347 | 2 |

| PQA-36 | 0.11 | 360 | 377 | 2 |

| PQA-39 | 0.15 | 387 | 410 | 2 |

| PQA-43 | 0.6 | 430 | 451 | 2 |

| PQA-47 | 0.13 | 470 | 493 | 2 |

| Unit of length is mm. | ||||

Q&A

- QCan I use tanks made by other companies?

- ACan not be used in third-party container.

- QDo you have any packing that is attached to the lid rather than put on the edge of the container?

- AB-type silicon packing [PQB] there is.

- QIs it possible to manufacture a material other than silicon rubber?

- AFKM (fluorine rubber), EPDM (ethylene propylene rubber), NBR (nitrile rubber), there is the option of CR (chloroprene rubber).

- QThe use in the tank that is already using want to know what size of

- AUse of tanks and packing photos, please let us know from the inquiry form and the inner diameter of the tank.

- QDo you have any packing material sample?

- AThere is packing sample. Please request from the left menu "technical booklet sample".