[gmp]

Smart selection of stainless steel containers by application

Three points that determine the grade of stainless steel containers

Stainless steel is a corrosion-resistant steel that contains 11% or more chromium in iron and forms a passive film

(oxide film) on the surface to improve corrosion resistance. It is also excellent in durability, fire resistance,

low-temperature properties, and workability. Based on these characteristics, stainless steel containers have also

been used for storage, storage, and transportation in the pharmaceutical industry.

However, storage and transportation have different usage purposes. If the environment and usage are different, the

appropriate quality of stainless steel container is necessary.

Yes, that’s right! There are different grades of stainless steel

containers.

So, what are the three points that determine the grade of stainless steel containers?!

1. Material selection

There are said to be over 100 types of stainless steel materials due to differences in structure and composition.

Different materials have different properties such as high strength, corrosion resistance, heat resistance,

seawater resistance, and formability. The choice of material affects the application and quality of the product.

2. Welding technique

There are containers that have been welded smoothly and without gaps, including vertical welding for the main

body, bottom welding, and flange and handle parts, and those that have not.

Even with the same material, the quality can vary depending on the welding technique.

3. Surface Treatment Technology

Even surfaces that appear smooth at first glance actually have tiny irregularities. The quality of the surface

treatment depends on how smooth these irregularities are and whether any polishing materials or oils remain. The

quality is affected by techniques such as buff polishing and electrolytic polishing.

We believe it is our mission to

propose the optimal quality of stainless steel containers that meet your site’s needs.

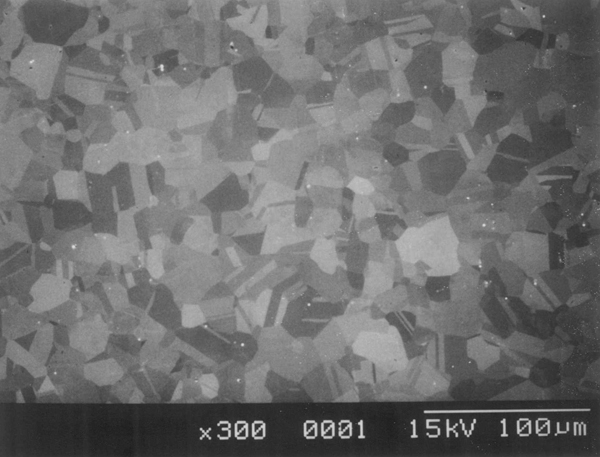

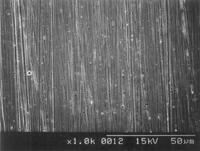

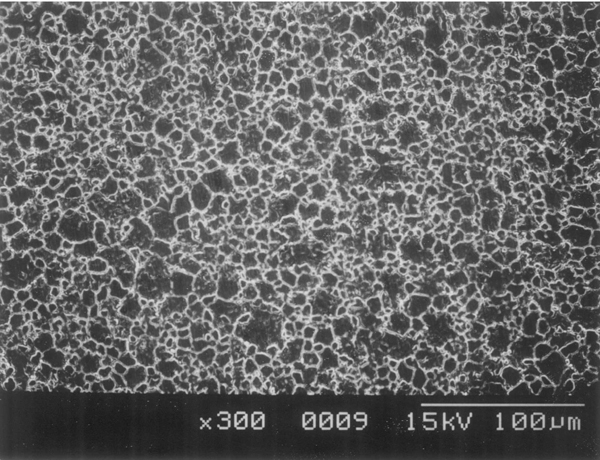

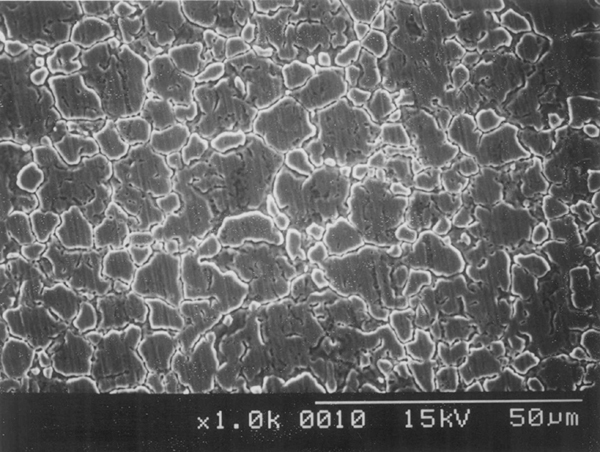

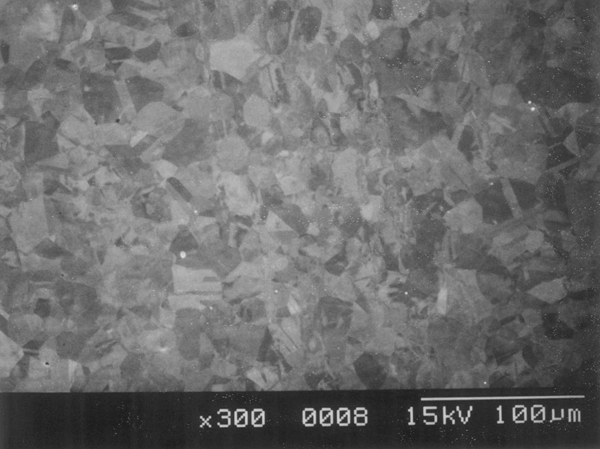

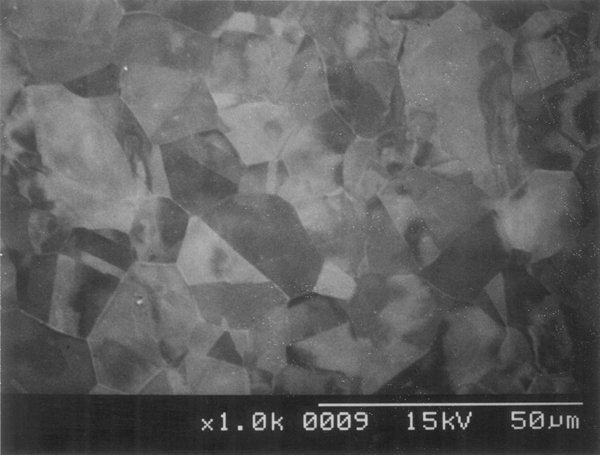

SEM images of stainless steel surfaces

Material

Stainless steel material commonly used in the pharmaceutical industry for equipment

Surface state with distinct roughness and unevenness

Easily attracts impurities and difficult to clean

Fingerprints easily visible and difficult to remove

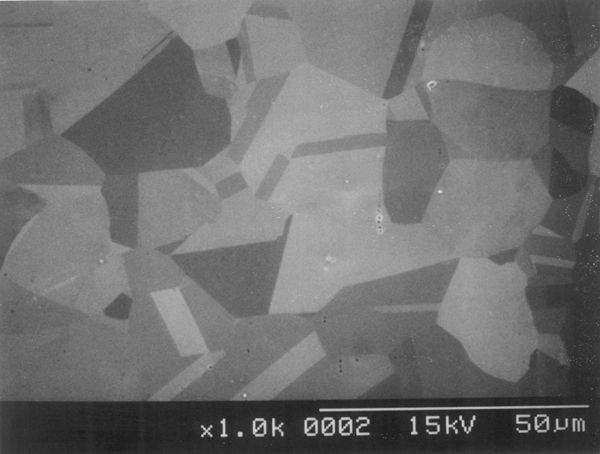

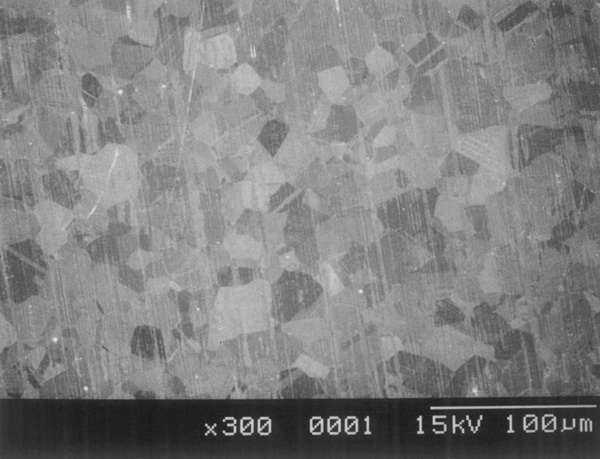

High-grade electrolytic polishing

316L/BA Material

Stainless steel material carefully selected by our company as a dedicated material for containers in

the pharmaceutical industry.

A flat surface with visible, clean metal crystals compared to 2B material.Fingerprints can be easily wiped off even when touched by hand.

![]()

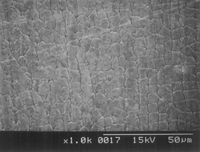

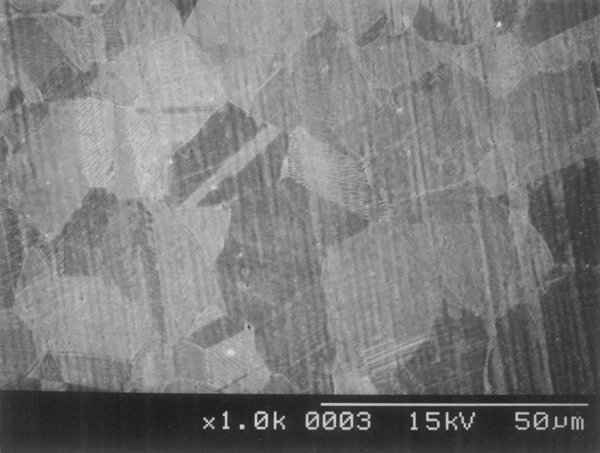

High-grade electrolytic polishing