Contribute to Pharmaceutical Quality

Stirring Units with High Sanitary Performance

Nitto Kinzoku Kogyo is a “stainless steel container manufacturer for the pharmaceutical industry”. We

have delivered numerous products to pharmaceutical manufacturers.

This is not only because we are skilled in high-sanitary specification products, but also because we are

well-versed in the grade required in pharmaceutical manufacturing sites.

Do you haveany of these concerns?

- Looking for a proposal for sanitary-grade agitation equipment, vessels, valves, etc. required for

pharmaceutical manufacturing - Not sure which agitation equipment or vessels to use to achieve the desired agitation

- Need to change the specifications for each unit according to production process, contents, and capacity

Nitto Kinzoku Kogyo

has all the solutions.

Three strengths of Nitto

Kinzoku Kogyo

1. Knowledge of pharmaceutical grade requirements

We manufacture high sanitary containers and stirrers that meet the high-grade requirements

demanded in pharmaceutical manufacturing. Our strength is in providing comprehensive proposals

for both containers and stirrers. We contribute to stable pharmaceutical quality.

2. Rich experience in custom-made products

We produce fully customized stainless steel container units tailored to your specific needs. With

our extensive experience in producing custom-made products, we can provide you with proposals

that go beyond your expectations.

3. Ideal for small lot production of multiple varieties

Our products, made one by one by welding, are ideal for small lot production of multiple

varieties. If you want to change specifications for each unit or just want to introduce one

unit, please consider Nitto Kinzoku Kogyo.

\ Please Tell Us About the Content and Quantity to Be Stirred /

1. Knowledge of pharmaceutical-grade

requirements

“I want to request high sanitary agitators altogether.”

We provide proposals for high sanitary agitators, containers, valves, and other peripheral equipment

required in pharmaceutical manufacturing sites all at once.

As a supplier with a large number of delivery records in the pharmaceutical industry, we are

well-versed in the grade required in pharmaceutical manufacturing sites. Based on this knowledge, we

can offer a product lineup and customized proposals. Therefore, there is no need to consult with

each agitator or container manufacturer. We can handle everything.

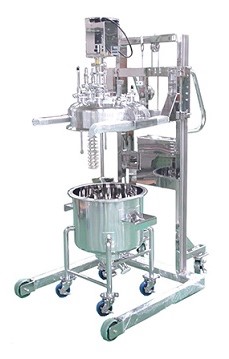

【Adopted by a pharmaceutical manufacturer】200L liquid blending tank

~High sanitary specification with electrolytic polishing and anti-contamination measures on the

inner surface of the container~

This container is used to make a coating agent that coats the surface of tablets. Raw

materials and pure water are added, and they are stirred using an air motor.

The agitator’s inlet is equipped with a cover for preventing contamination, and a

discharge valve is used to discharge the contents completely. It is a high sanitary

specification with these measures.

The inner surface of the container is subjected to electrolytic

polishing, a polishing method that smoothes the surface by dissolving metal

ions, which enhances cleanability and hygiene and improves

corrosion resistance. It is the ideal product for

pharmaceutical manufacturing sites.

2. Abundant Custom-made Examples

“I want to stir high viscosity liquids.”

“I want to stir while minimizing the risk of contamination.”

First of all, please tell us your requirements. At Nitto Kinzoku Kogyo, we manufacture fully

custom-made stainless steel container agitators.

If your current equipment is not working well for stirring, please let us know about your situation,

and we will analyze the reasons why stirring is not working based on

our abundant examples of agitator manufacturing. Based on that, we will propose the

optimal design and processing to solve your concerns.

【Adopted by Pharmaceutical Manufacturers】Pressure-Reducing Jacketed Container with Magnet Type

Agitator

~Two agitators installed to dissolve and defoam powder and liquid~

This is a container for dissolving powder and liquid, defoaming, and then pressurizing

and sending the mixture to other equipment.

Water heated by a chiller circulates in the jacket part of the container, and the

contents are temperature-controlled and heated. Two

magnet-type agitators installed on the top and bottom of the container stir

the heated contents.

Then, the generated foam is defoamed by reducing pressure, and the solution is

pressurized and sent to other equipment.

Since a tank bottom valve with little dead space during

stirring is used at the discharge port, stirring can be efficiently

performed.

3. Ideal for producing multiple

varieties in small quantities

Our products are ideal for production sites with small-scale

production of multiple varieties and in the

prototype stage. We provide agitation units tailored to each production process,

adapting to the contents and existing equipment at the time.

We adjust the size to fit your needs, perform additional work to streamline the process,

andcontribute

to the efficiency of the production process.

\ Attach Punch Drawings and Diagrams Too /

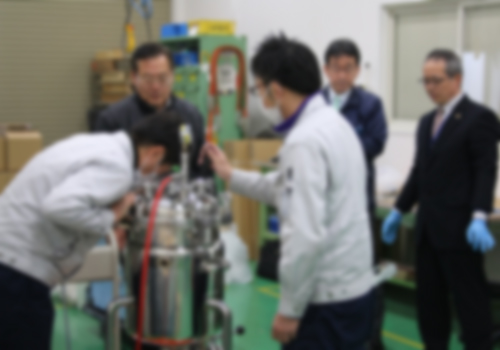

“When you want

to check the ease of use before purchasing”“When you

want to actually try stirring”

We also offerdemo and

rental services.

If you want to

- try stirring the materials you will actually use before purchasing

- confirm that it can be stirred without any problems

please use our demo/rental service before purchasing.

We will propose a demo product based on your usage, challenges you want to solve, and what you want to

confirm with the demo/rental. Based on the results obtained, we will consider the optimal specifications

for you.

Confirm Product Specifications and Get a Quote Here

\ We solve your problems /

If you have already decided on the

specifications, use this.

Contact by Phone or FAX

Contact by Phone

048-996-4221Weekdays 9am-5pm

Contact by FAX

048-996-8781

Available 24 hours

FAX form is also available.

Please print and use it.