Here’s the solution!

Beak Agitator

Our Beak Agitator is uniquely designed to reduce the inclusion of air from the liquid surface and

suppress

foaming during stirring. This is particularly useful for high-viscosity liquids that require substantial

defoaming time after stirring. Furthermore, it allows accurate measurement by preventing foam formation

on

the liquid surface after stirring. Lastly, this design helps prevent overflow when stirring liquids that

tend to foam easily.

The Advantages of the Beak Agitator

- Reduces the inclusion of air from the liquid surface and suppresses foaming during stirring

- Helps prevent overflow when stirring liquids that tend to foam easily

- Allows accurate measurement by preventing foam formation on the liquid surface after stirring

Product Information

Please feel free to contact us for more detailed product information.

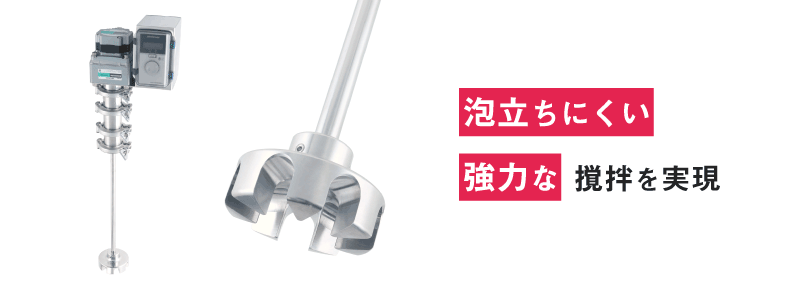

Powerful stirring while suppressing foam! The Bernoulli Agitator has the solution.

What is the

Bernoulli Agitator?

The Bernoulli Agitator, equipped with the “Bernoulli Flow Stirring Body (BEAG)”, generates a liquid flow

in

the container through a different principle (pressure difference by centrifugal force) than general

stirring

bodies. This makes it possible to achieve a “hard-to-foam”, “powerful” agitation.

It is mainly suitable for stirring about 30 to 300 liters.

\ Please tell us “for what purpose”, “what”, and “how much”

you

want to stir /

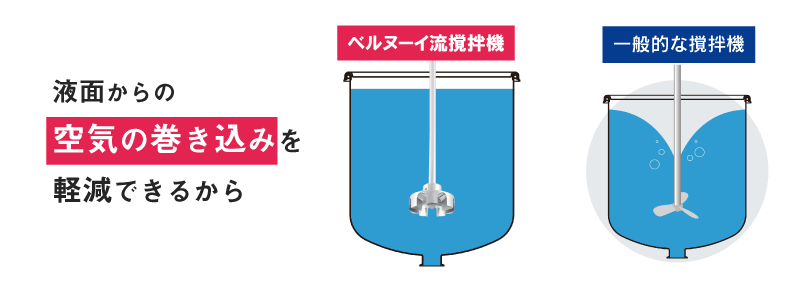

The Reason It’s “Less

Likely to

Foam”

There are several factors that contribute to foaming. One of them is “air being drawn in from the

surface of the liquid during agitation”.

The surface of the liquid around the stirring shaft drops due to the swirling flow, creating a

large

vortex in the center of the container, which causes foam to form.

In this agitator, we reduce the air entrainment from the liquid

surface.

This suppresses foaming, shortens the time required for defoaming in the subsequent process, and

prevents foaming and overflow of the liquid surface.

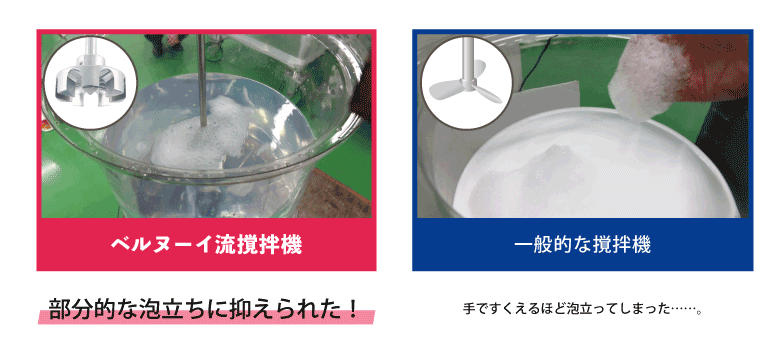

Does it really not foam? We stirred water with detergent to test.

Compared to a typical propeller agitator, the result is…

The Bernoulli Agitator was able to significantly suppress

foaming.

Click here for those who want to see the

details of the detergent agitation experiment video

\ Attachments of sketches and drawings are also

possible

/

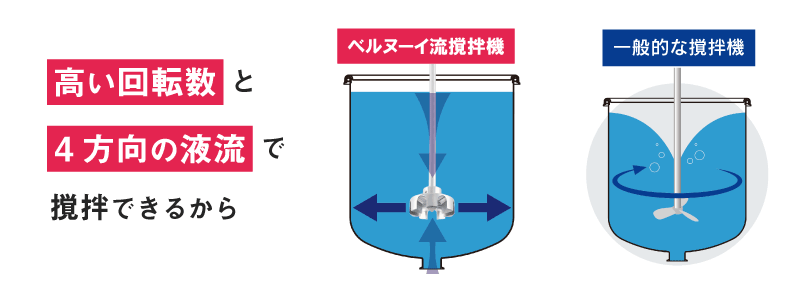

The Reason for “Powerful Agitation”

The agitator has a shape that is resistant to resistance, allowing high-speed agitation even with a compact motor

(700rpm~).

In addition, the liquid flow generates in four directions: up,

down,

left, and right, improving agitation efficiency and achieving powerful agitation.

Voice from a pharmaceutical company that actually uses it

“By introducing this agitator into the dissolution process of active pharmaceutical

ingredients,

we were able to reduce the dissolution time by 30% compared

to

conventional methods. It is an excellent agitator that is also effective in

preventing foreign substance contamination and can be used with confidence even in stringent

sanitary environments.”

A Reliable Agitator for Use in Stringent Sanitary Environments

Excellent in Foreign Substance Contamination Prevention

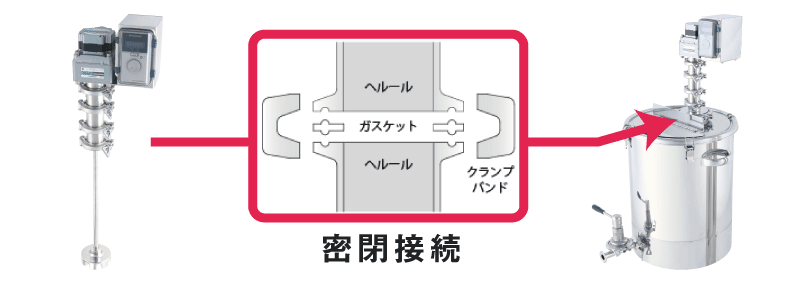

○ Connect the container and agitator with “Zero Gap”

This agitator is securely connected to the lid of the container with a “Ferrule fitting”.

There is no gap between the lid and the agitator, allowing you to prevent foreign substance contamination from the agitator

connection area.

○ Easy-to-clean structure for cleaning the

wetted

parts frequently

The shaft (agitator shaft) and agitator, which come into contact with the liquid, are

designed for easy cleaning.

The shaft is easy to detach compared to agitators with

conventional sealed connections and can be disassembled with just a hex

wrench.

It can be quickly disassembled even without advanced technical skills, allowing for

smooth

transition to cleaning.

Moreover, the agitator has a simple shape without fine

gaps,

making it easy to clean.

Even in processes that require frequent cleaning or in the production of multiple

products,

you can easily disassemble and clean without spending much time, allowing for a smooth

transition and reliable production.

\ Attachment of sketches and drawings is also possible /

About Us

[Sales Division]

358 Nitchou, Yashio-shi, Saitama 340-0811, Japan

Phone: 048-996-4221 Fax: 048-996-8781

[Yashio Factory (ISO9001 Certified)]

358 Nitchou, Yashio-shi, Saitama 340-0811, Japan

Phone: 048-996-4221

[Tsukuba Factory (ISO9001 Certified)]

Suwa C25 Block, Tsukuba City, Ibaraki 300-2658, Japan

[Headquarters]

2-53-2 Nihonbashi Hamacho, Chuo-ku, Tokyo 103-0007, Japan

- Manufacturing and sales of industrial stainless steel containers

- Stainless steel sealed containers

- Storage containers

- Transport containers

- Pressure vessels

- Preservation containers

- Various other equipment

Partial exports to major pharmaceutical companies in the United States (Merck, Baxter, etc.)

“I want to know detailed specifications and prices!” “Is it possible to use it in

this

way?”

For inquiries and quotation requests, please contact us here

\ We’ll solve your concerns /

Contact us by phone

Phone Inquiry

048-996-4221 Weekdays 9:00-17:00

Fax Inquiry

048-996-8781

24-hour reception

FAX Form is available.

Please print and use the form.