Improve Work Efficiency with Custom-Made Stainless Steel Tanks

Do you have these concerns?

- “The existing tank is not suitable for female workers’ height.”

- “I want to ensure maximum capacity in a limited space.”

- “The fluidity of the liquid is poor, making it take time to discharge to the next process.”

Improve work efficiency with custom-made proposals

1. Proposals tailored to processes and people

2. Proposals tailored to equipment and space

3. Proposals tailored to the contents

Over 120,000 custom-made achievements!

Over 120,000 successful cases of using custom-made tanks

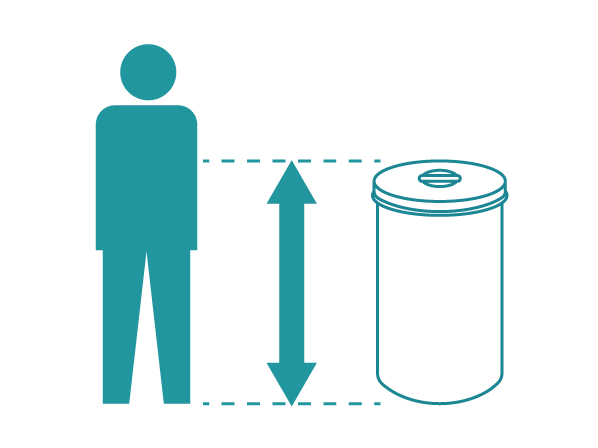

1. Proposal tailored to the process and personnel

Added a work table for temporary placement during input operations. Designed to match the height of female workers.

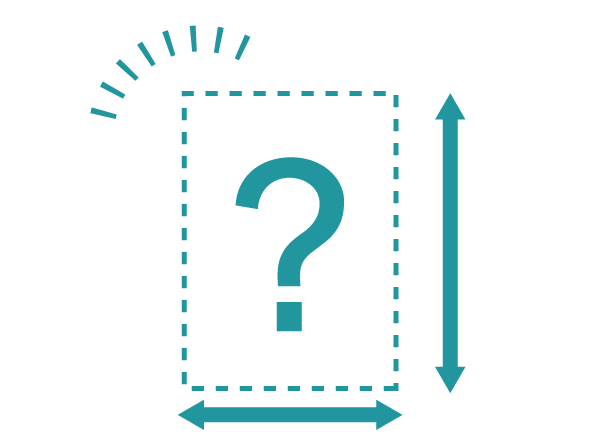

2. Proposal tailored to equipment and space

Designed with a container diameter and height that fit the space, allowing maximum storage capacity in a limited space.

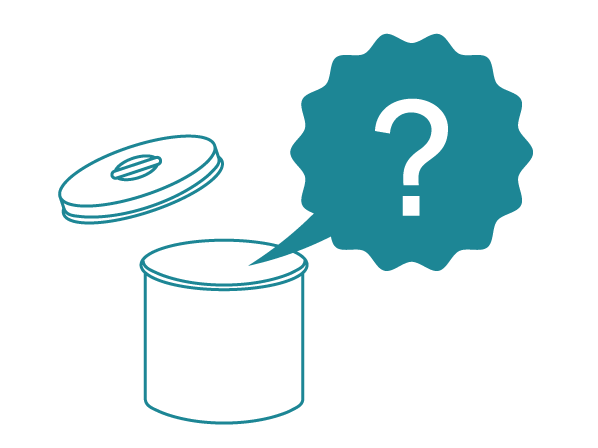

3. Proposal tailored to the contents

In order to smoothly discharge high viscosity paint, the

bottom of the container is inclined to ensure smooth discharge to the next process.

Here’s what sets us apart from other companies:

A lineup of container shapes that can be selected according to the application

storing finished products that need to be kept clean…

You can choose according to the usage process, which leads to more efficient work.

A wide range of accessories for greater usability

container and jacks to assist in the detachment of valves, also support work efficiency.

Produced at an ISO 9001 certified factory for quality management

We manufacture our products at a factory that has obtained the international quality management

standard, ISO 9001 certification. We strive to improve our quality through clear production

processes and reviewing our procedures.

*Certification obtained at our Yashio factory.

Company Overview

- Company Name

- Nitto Kinzoku Kogyo Co., Ltd.

- Representative Director

- Koichi Oyama

- Address

-

[Sales Department]

358 Nitchoume, Yashio-shi, Saitama 340-0811, Japan

Phone: +81-48-996-4221 Fax: +81-48-996-8781[Yashio Factory (ISO 9001 certified)]

358 Nitchoume, Yashio-shi, Saitama 340-0811, Japan

Phone: +81-48-996-4221[Tsukuba Factory (ISO 9001 certified)]

Suwa C25 Block, Tsukuba-shi, Ibaraki 300-2658, Japan[Head Office]

2-53-2 Hamacho, Nihombashi, Chuo-ku, Tokyo 103-0007, Japan - Establishment

- June 1957

- Capital

- 32 million yen

- Number of Employees

- 130

- Business Activities

- [Stainless Steel Products Department]

- Major Clients

- Pharmaceuticals, chemicals, cosmetics, food industry, research laboratories, other industries

Some products are exported to major American pharmaceutical companies (Merck & Co., Inc., Baxter

International Inc., etc.)

Confirm product specifications and request a quote here

\ We will solve your problems /

This is convenient for those who have

decided on specifications

Inquiries by phone or fax

Phone inquiry

048-996-4221 Weekdays 9:00 am to 5:00 pm

Fax inquiry

048-996-8781

Available 24 hours

We also have a FAX form.

Please print and use it if it’s convenient for you.