At Nitto Kinzoku Kogyo, stainless steel containers are made by welding

plates together, not by press molding.

Here, we will introduce how stainless steel containers are made.

plates together, not by press molding.

Here, we will introduce how stainless steel containers are made.

Nitto Kinzoku Kogyo is a manufacturer that handles everything from design to production of stainless

steel containers in-house. After welding, we use our original technology for processing to enhance the

value of our products.

Accepting the Materials

This process involves accepting the purchased materials.

We check that the ordered materials have arrived without error and have no scratches.

We check that the ordered materials have arrived without error and have no scratches.

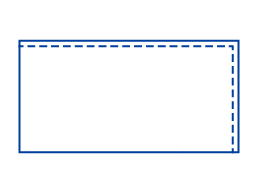

Cutting the Materials

This process involves cutting the materials to a predetermined size using a

technique called “shearing”.

There are also cases where materials of a predetermined size have been cut and purchased.

technique called “shearing”.

There are also cases where materials of a predetermined size have been cut and purchased.

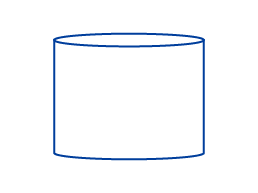

Round the material

This is the process of rounding the material boards that will become

the body of the container, called “roll”. If this process is not done well, it will affect

the subsequent process.

the body of the container, called “roll”. If this process is not done well, it will affect

the subsequent process.

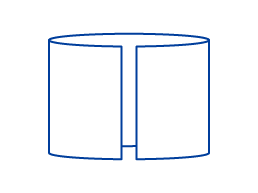

Make it a cylinder

This is the process of welding the rolled board to make the cylindrical

body of the container. It is produced by adjusting the material, thickness, and temperature

of the board.

body of the container. It is produced by adjusting the material, thickness, and temperature

of the board.

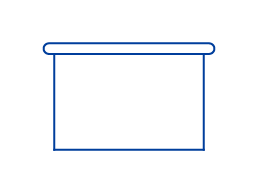

Curl one end of the cylinder

This is the process of curling one end of the cylindrical body of the

container, called “curl”. The edge-wrapping part of the container is made here.

container, called “curl”. The edge-wrapping part of the container is made here.

Attach the bottom

This is the process of welding the body and bottom of the container to

make the container. Care is taken to ensure that there are no gaps or holes when welding.

make the container. Care is taken to ensure that there are no gaps or holes when welding.

Polishing

This process involves polishing the surface of the container to make it

smooth and give it a glossy finish.

The surface of the stainless steel container is polished using a “buff” coated with

polishing material such as cloth.

smooth and give it a glossy finish.

The surface of the stainless steel container is polished using a “buff” coated with

polishing material such as cloth.

Cleaning

This process involves cleaning to remove general dirt.

The finished product is checked for defects while being washed.

The finished product is checked for defects while being washed.

Assembly and Inspection

This process involves assembling the product and checking its

quality.

Inspections are performed based on customer requests.

quality.

Inspections are performed based on customer requests.

Packaging, Wrapping, and Shipping to You

This is the final step in delivering the finished product to you.

We carefully package and wrap each product according to its specifications and destination.

We carefully package and wrap each product according to its specifications and destination.