Aeration Hopper

Features

An accessory designed to eliminate powder blockages such as rat-holing and bridging, ensuring smooth discharge. It is attached to the hopper outlet for use.

Product Specifications

Material: SUS316L

Supply Pressure (Approx.): 0.1 MPa

Inner Hopper Diameter: φ200 mm (fixed)

Discharge Port: 2S ferrule (fixed)

Air Supply Hose Outer Diameter: φ10 mm

Note: Gaskets used at the aeration hopper connection are not commercially available. Please contact us for replacements.

Patent No. 7624753 (JP)

Reference Dimensional Drawing

Drawings & Certificates

Request Drawings & Certificates / Contact UsDetails & Notes

Move Powder Like a Liquid for Smooth Discharge—Reduce Labor and Material Loss

Connect air to operate. Air flows into the hopper, fluidizing the powder to promote smooth discharge.

Excellent Cleanability to Prevent Cross-Contamination

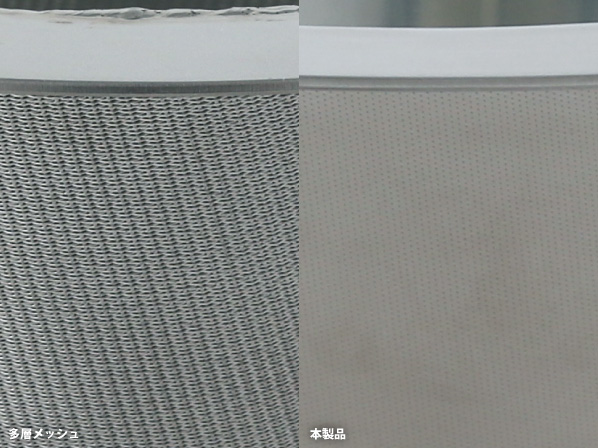

The inner hopper is equipped with fine holes through which air is introduced.

These holes have a nearly straight structure, making them easier to clean than multiple layers of mesh with varying roughness, even if some powder enters. This design helps reduce the risk of contamination when multiple product types are produced on the same line, or in industries—such as pharmaceuticals—that require very high levels of hygiene.

Q&A

- QCan I purchase this item separately and attach it to an existing hopper?

- AGenerally, this is not possible. We recommend purchasing it along with the hopper, as it requires a specially sized fitting at the connection. Our company can manufacture the hopper for you. Please contact us with your desired capacity and any other requirements.

- QIs it also effective for damp (moist) powders?

- AGenerally, it is not recommended for damp powders. However, depending on the material properties and conditions, it may still be effective. We can conduct tests using your actual powder, so please contact us for more information.

- QCan the size be changed?

- ANeither the discharge port nor the hopper’s top diameter can be modified.