MFV-F : rule type choke valve to

Features

Granular is the control valve for the body. Also known as the iris valve.

Discharge of the powder particles, have been used as input for the valve.

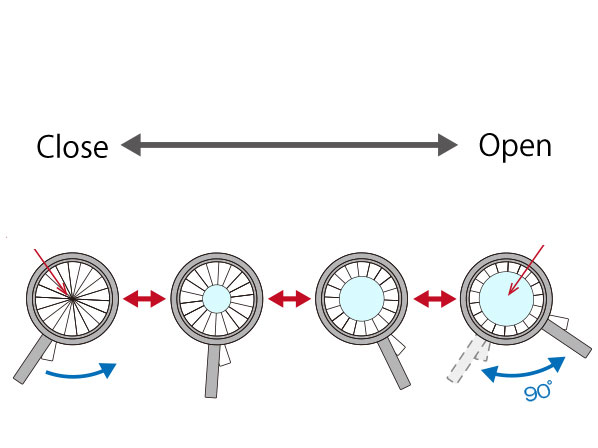

○ sleeve choke rope outside (valve) opens and closes smoothly as lens shutter.

○ powder contact portion is covered with a cloth, there is no gap powder from entering.

Since there is no sliding parts and obstacles to ○ passing surface, it does not damage the contents.

○ connect or disconnect is easy because the ferrule connection type.

○ sleeve can be easily replaced and cleaned can be inserted or removed with one touch.

○ flow rate adjustment can be done freely in the handle.

You can change the material of the sleeve according to the ○ contents.

○ ferrule is using a paid industrial 20 ° low-pressure ferrule (flat packing).

Product Introduction Video

Product Specifications

Selected from the casing material ... SUS304 or aluminum + fluorocarbon resin treatment

Sleeve valve ... antistatic finish with polyester

Drive ... manual

Caliber and connection size ... See Appendix

-Notes-

※ ruled uses the industrial 20 ° low-pressure ferrule.

※ packing is flat packing.

Please contact us ※ other size.

If the ? discharge side does not connect the piping

Holding ferrule to prevent falling off of the sleeve valve is required. (Sold separately)

If you want to connect a pipe to the ? discharge side

And an inner diameter mounting inner diameter of the choke valve (.phi.D2) and the same dimensions, please keep hanging down length corresponding linear portion of the time to open the sleeve valve.