TSC : Torque Management Socket for Clamp Band (Lost-wax casting)

Features

Socket for Clamp Bands

Standardize clamp band tightening torque by using this socket in combination with a torque wrench.

- To use, attach the socket to a torque wrench and insert the wing nut of the clamp band into the groove on the socket surface.

- By setting the desired torque on the wrench, you can prevent inconsistencies in tightening.

- This single socket is compatible with clamp bands of various sizes and manufacturers.

- The TSC socket is available in three sizes to match different torque wrench connection types, but the groove size is identical across all variants.

- All three sizes are compatible with our bottles.

- We also offer custom design and manufacturing to match the clamp bands you currently use.

※Torque wrench sold separately.

Price:

Product Specifications

Material ... SCS13

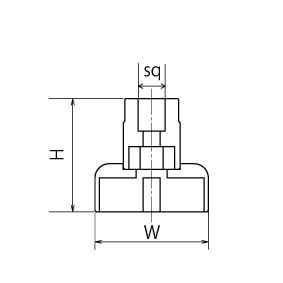

Reference Dimensional Drawing

Drawings & Certificates

Request Drawings & Certificates / Contact UsDetails & Notes

| Weight | Drive Size | Width | Overall Height | Lead Time |

|

|---|---|---|---|---|---|

| Model | kg | sq | W | H | Days |

| TSC-01 | 0.13 | 6.35 | 37 | 30 | 2 |

| TSC-02 | 0.13 | 9.5 | 37 | 30 | 2 |

| TSC-03 | 0.15 | 12.7 | 37 | 35 | 2 |

Q&A

- Q I would like something that matches the clamp I have.

- ASo that we can manufacture according to the specifications of your existing clamp, please contact us.

- QCan you also made in other sizes?

- APlease tell us the dimensions and the like hope.

- QCan I use in this clamp band?

- APlease see the here .

- QWhat is the difference between the TSC-01/02/03?

- ADepends on the size of the place (the insertion angle sq) that plugs into the torque wrench.