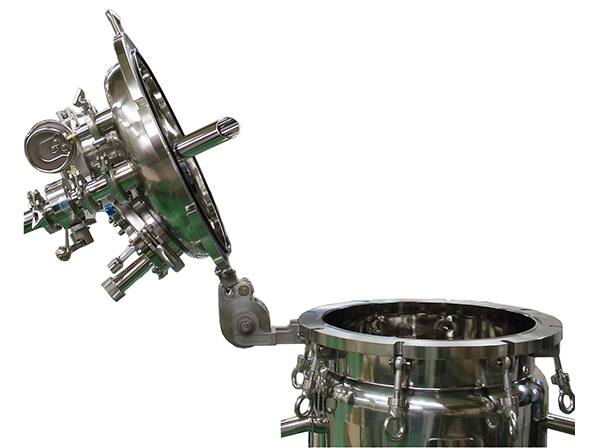

Addressing / Dressure Jacket Container Magnet with Stir

Features

Pharmaceutical manufacturer delivery

○ It is a custom-made case of stainless steel pressure vessel unit used to dissolve powder and liquid and pump it to other equipment.

A stainless steel pressure vessel combines peripherals such as a magnet stirrer (stirrer / hollow machine), a thermostat water circulation device, and a vacuum pump.

To the liquid placed in the container, the powder material is gradually introduced from the plague fly valve eccentric hopper.

The input content is temperature-sensitive with warm water circulated to the jacket and mixes with the upper and lower stirrer.

The foam generated during stirring is degraded by decompressing.

Electrolytic polishing was performed on the inner surface of the container.

The state in the container can be confirmed from the peek window (site glass).

The windows are installed with lights and wipers for illumination to improve visibility.

The completed solution is discharged from the tank bottom valve and pumps through the tube strainer to another device.

Product Specifications

Dimension container: inner diameter φ396 × height 524 mm

Jacket inner diameter: φ450 mm

Total height: 1680 mm (including stirrer)

Capacity 30L

Material SUS316L

Surface treatment inner surface # 400 after polishing, electrolytic polishing

External # 320 buff polishing

Voltage-0.1 MPa-0.18 MPa

Parts Liquid Flow Pipe, Liquid Pipe, Safety Valve

Tube strainer

Lid opener (with stopper)

Ferrule-type diaphragmatic synthesis

Temperature sensor

Peripheral device Magnet type stirrer (vertical / bottom mounted)

Eccentric hopper with butterfly valve

Manual tank bottom valve

Peep window (flash light, wiper)

Constant water circulation device, temperature indicator, vacuum pump

Management number 1O008765