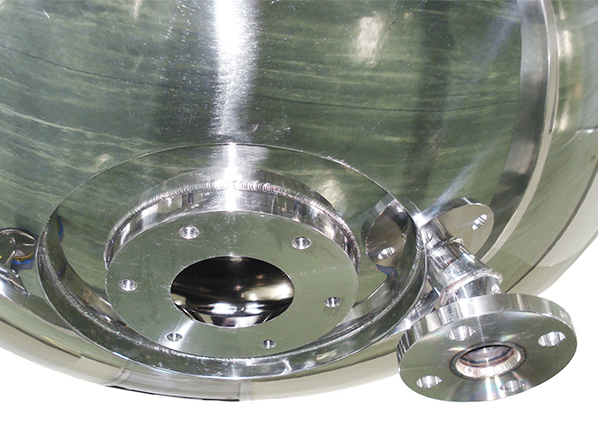

Flange Open Pressure Vessager Jacket with Bagacking, Exterior Heat Heat, Various Accessories

Features

Chemical manufacturing manufacturer delivery

○ It is a custom-made case of stainless steel pressure vessel used for heating and dissolution agitation of the material.

It dissolves with a stirrer (stirrer / hollow machine) while heating the material that dislike contaminated.

The ingress of the material is performed through the diaphragm valve.

In light of the container with flash light, check the internal dissolution status from the volatile window.

All the liquid contacts are electropolished.

Discharge contents with a tank bottom valve with little liquid reservoir.

Pure water washed with shower ball in the container after discharge.

In order to insert internal heat retention and burn prevention, insulation is wound on the jacket exterior.

Containers and mounts can be separated.

Product Specifications

Dimension container: φ 700 mm × H1045 mm

Total height: H1445mm (including bag)

Capacity 300L

Material Body: SUS316L Mountain: SUS304

Surface treatment container: inner electrolytic polishing + passivation processing,

Exterior # 320 Buff Abashing Mountain: # 320 Buff Polishing

Volt-resistant vessel: -0.1 to 0.15 MPa

Jacket: -0.1 to 0.3MPa

Nozzle ferrule fitting 1.5s, 2s, 3s, 4s, 6s

Flange fitting, tank bottom valve

Other safety valves, diaphragm type pressure gauge

Lighting equipment: flash light

Diaphragm Valve, Peep Window (3S)

Shower ball, insulation

Document size, appearance, water pressure, airtight examination

Mill sheet, electrolytic polishing certificate

Management number 1n001496