Temperature conditioning unit separated jacket with stirred container

Features

Pharmaceutical manufacturer delivery

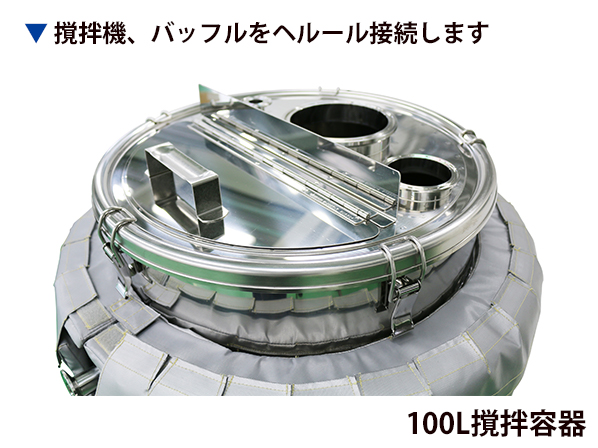

○ It is a custom-made case of container that can stir 100 L liquid containing insoluble powder.

This product is a product consisting of a jacket with a stirred container and a temperature control unit (hot water circulation device).

The jacketed and stirred container is highly stimulated [DTM-J] Custom-made processing based on a stirring machine-type jacket container.

Manual tank ball valve is adopted for the outlet. It is difficult to resemble because there is no junction or not.

It is difficult to involve the air, and adopts a Bernouwir flow stirrer ([NTME-A]) with uniform stirring. Standard equipment controllers are easy to change the number of revolutions.

The temperature adjustment unit is attached to the carriage with the control panel and the pump and can be moved.

Water water made of temperature control unit is supplied to the jacket of the stirring vessel via the heat-resistant hose and circulates. This will warm the liquid in the container.

Also equipped with a stirring vessel and a temperature control unit [ECK] Insert a thermal insulation cover. Not only the heat retention effect, but also leads to the infrastructure prevention of worker.

The reason why the stirring temperature control function is separated

Product Specifications

◆ Gacket with a jacket

Container diameter φ470 mm

Container height 1040mm

Total height 1480mm (at the time of stirrer installation)

Capacity 100 L (jacket 24L)

Container material SUS304

Pressure 0.19 MPa (jacket part)

Temperature 133 ° C (jacket part)

◆ Temperature conditioning unit (hot water circulation device)

Container diameter φ565 mm

Container height 730mm

A total height 1170mm (Castor-Top of Control)

Capacity 150L

Container material SUS304

Power supply 3 phase 200V

Usage temperature 80 ° C (heater)

Management number 1W001924