In a CBD production plant, it is very important to control the storage conditions of the product. In some cases, highly cleanable tri-clamp rings are used for piping in production equipment.

Tri-clamp rings do not require tools and can be installed manually, but the disadvantage is that the tightness of the clamp ring is determined by the operator’s senses and experience.

When we talk about “tightening” something, we tend to think to tighten something so firmly that the object is fixed and does not move.

However, “tighten it firmly” is not necessarily equal to “tighten it strongly”. It is important to tighten with the appropriate torque. Excessive tightening risks deforming or damaging the parts.

Another equally important issue is to be careful about gasket overflow due to over-tightening. The gasket between the piping or between the lid and the container may protrude inside or outside the container or piping, resulting in poor sealing or foreign matter contamination.

In this column, we will focus on the inside protrusion of the ferrule gasket. We will also conduct an experiment to see how much the gasket protrudes depending on the tightening torque when ferrule is tightened with a tri-clamp.

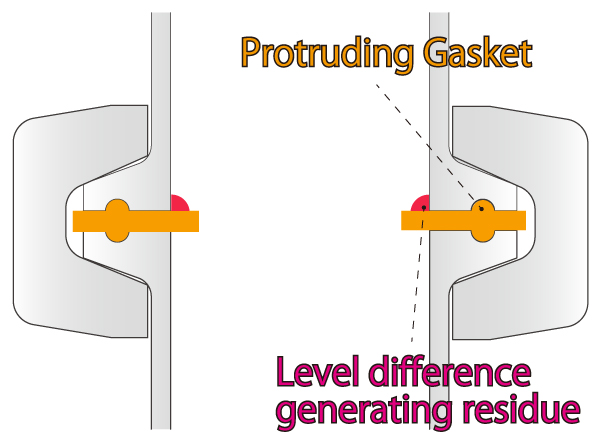

1. The protruding gasket can cause contamination.

If the gasket between the ferrule protrudes into the piping or container, it may cause contamination. Please see the following two cases:

1. When the gasket itself becomes contaminant

If the gasket protrudes, the protruded part may be worn out and may enter the container.

In particular, if the gasket of the connection part with piping and accessories is protruding, it is very easy to be worn out on that part.

It is risky that the worn-out part may get mixed into the container, or the deteriorated gasket may be torn and its fragments may get mixed into the content material.

2. When residues adhering to the uneven part of the gasket, it will become contaminant

The protruding gasket makes a level difference between the inner wall and the gasket (uneven part). If the content remains or adheres to this uneven part, there is a possibility that the residue may drop off and contaminate the content.

Residues can be removed by periodic cleaning, but these residues can be reduced by preventing the gasket from sticking out in the first place.

The uneven part may also cause a decrease in liquid delivery efficiency.

If there is a difference in level in the piping, it will become a dead space, and it will become an obstacle for sending liquid. In order to maintain the efficiency of fluid delivery, please tighten the clamp with appropriate force.

2. Comparison of protrusion of gasket by tightening torque

Let’s do an experiment to see the relationship between protrusion and the tightening force.

Insert the silicone rubber gasket between the pipes and tighten with the tri-clamp band.

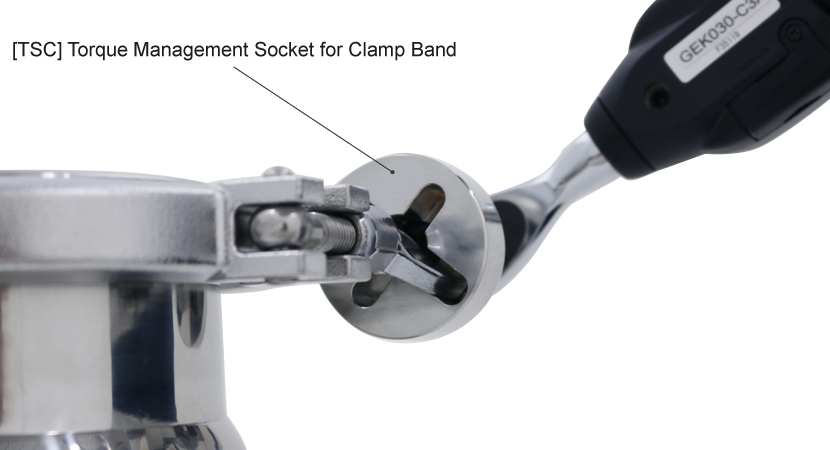

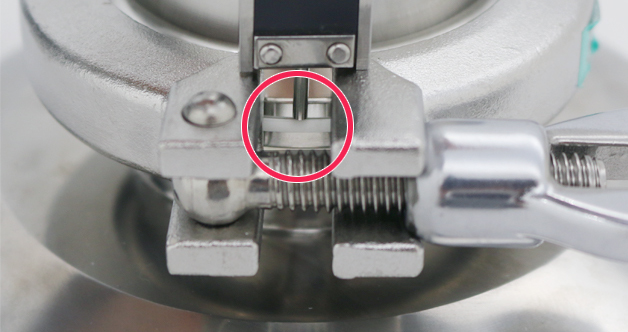

First, check the condition of manual tightening, then use a torque wrench and [TSC] torque management socket for the tri-clamp band, and tighten the clamp with a torque of 3 N · m ~ 10 N · m.

The last step, we will check the pop-out of the gasket by visual observation and the change of the inner diameter of the gasket.

What is “Torque”?

“Torque” refers to a force that twists an axis or rotates an object.

In particular, the torque used to tighten screws, etc., is called “Tightening Torque” and is generally expressed in units of N ・ m.

Torque wrench is a tool for measuring and displaying this value.

For 4S-size situation

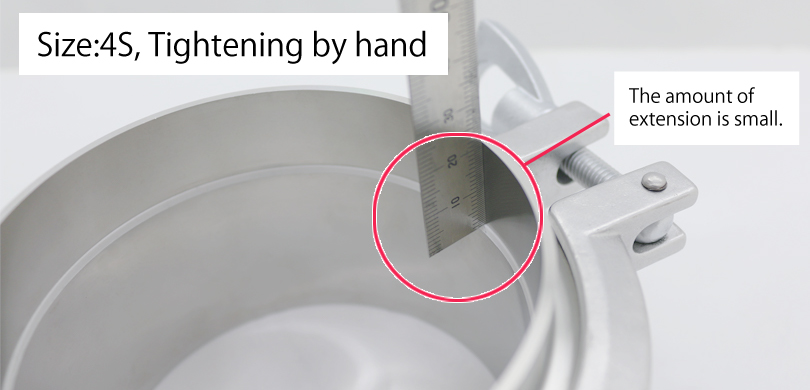

First, let’s make the experiment with ferrule and size of 4S (IDF/ISO standard).

First of all, let’s check what the gasket is like by tightening it by hand without using a tool.

Even when it is tightened by hand, there is still a little protrusion that can be seen. The inside diameter of the gasket is 96.86 mm.

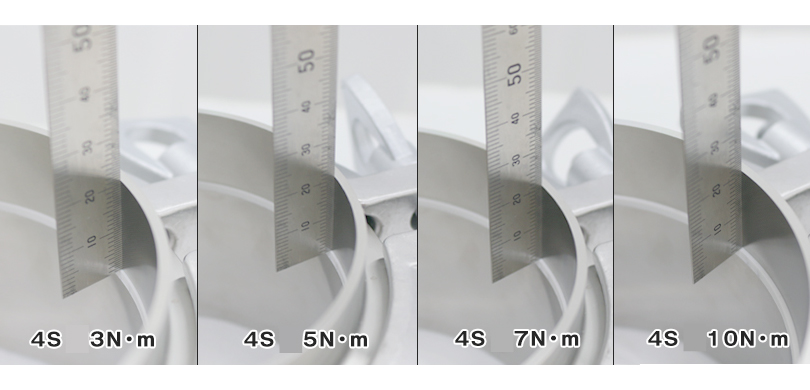

Next, let’s check how the bulge and inner diameter change as the tightening torque increases. Since the torque wrench used this time cannot measure 3N · m or less, manual tightening torque is not described.

It may be hard to see the difference in the picture, but when you measure the value, you can see that the inner diameter of the gasket decreases as the torque increases.

| Tightening Torque(N・m) | By Hand | 3.04 | 5.08 | 7.00 | 10.28 |

| I.D(mm) | Φ96.89 | Φ96.34 | Φ96.19 | Φ95.89 | Φ95.38 |

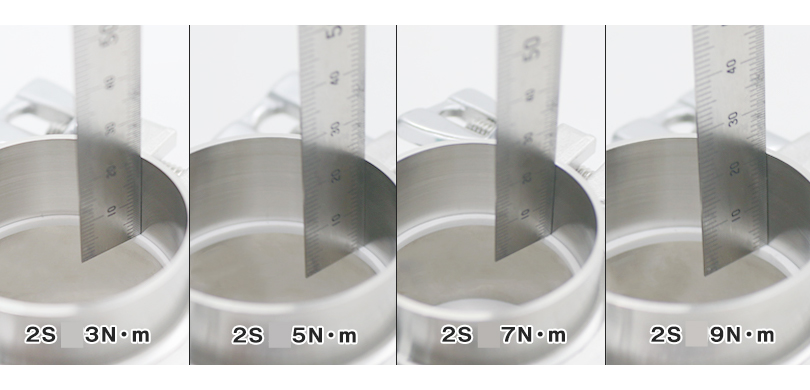

For 2S-size situation

Similarly, let’s check out the situation of 2S-size ferrule.

If you tighten it by hand, it will be in the following state. The inner diameter of the gasket is 46.93 mm.

You can see that in 2S’s case, there is a larger change in the protrusion than 4S. Even when the tightening torque is approximately 3 N · m, the product protrudes more than when tightening by hand can be observed clearly. The numerical changes are as follows:

| Tightening Torque(N・m) | By Hand | 3.02 | 5.24 | 7.10 | 9.20 |

| I.D(mm) | Φ46.93 | Φ45.95 | Φ45.26 | Φ44.89 | Φ44.47 |

In the case of 4S, the inner diameter decreased by approximately 1 mm when tightening from approximately 3 N · m to 10 N · m, whereas in the case of 2S, the inner diameter decreased by approximately 1.5 mm when tightening from approximately 3 N · m to 9 N · m.

Outward extrusion

It can be confirmed that the tri-clamp ring protrudes outward from the gap. The outward protrusion was smaller than the inward protrusion, and it did not protrude in the case of 4S.

Just because the outside doesn’t protrude doesn’t mean the gasket won’t protrude inside, so please be careful about this issue.

3. For avoiding excessive tightening

In this experiment, we confirmed that the gasket protruded inward in both 2S and 4S cases.

Generally, the appropriate tightening torque is around 3N · m. Therefore, it is necessary to allow the gasket to protrude at a time of about 3N · m, but if the tightening torque is stronger than that, it will create dead space/uneven parts, which unnecessarily increases the risk.

To eliminate this risk and waste, it is desirable to tighten the clamp lightly by hand and then use a torque wrench to tighten the clamp appropriately.

The [TSC] torque management socket for the clamp ring is ideal for this kind of need. By attaching this socket to a commercially available torque wrench, the tightening torque of the clamp band can be measured. This product prevents excessive tightening and helps standardize tightening torque.

Since it is compatible with clamp rings of multiple manufacturers and models, it is safe for you to have this one. Even if the standard product is not available, we can customize it to fit your special needs, so please feel free to contact us.

4. Summary

When tightening the tri-clamp band, it is not always necessary to use very strong force. As you can see from this experiment, if the seal is tightened more than necessary, the gasket sealing will protrude, causing various risks.

Torque control is essential to prevent this situation from happening. Ideally, all operators should be able to tighten with appropriate torque under any circumstances.

In addition to the “TSC ” introduced at Nitto Kinzoku Kogyo, we can produce custom-made products such as “Torque-controlled bottles“; and in response to customer requests, we also have a “special gasket with a SS ring on the outer circumference” that does not easily protrude inwards. Using torque-management tools can reduce unnecessary risk and waste, which is important and essential in the manufacturing process.

Tag Related Posts

- No related posts.