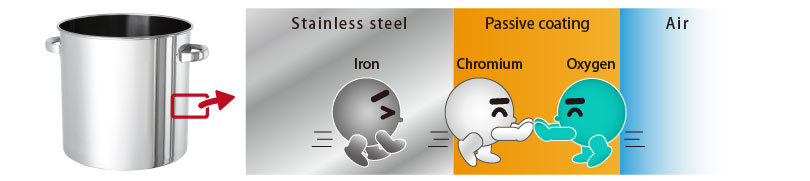

Stainless-steel containers are often used at work, in factories, at home, as containers for storing raw materials, and as cooking utensils. Among those stainless-steel containers, there may not be too many people know “slant-bottom container” yet.

This time, we will introduce “slant-bottom container” which is a little different from ordinary containers.

What is a "Slant-Bottom" Container"?

A slant-bottom container has a bottom sloping toward the outlet. So, even if the container is not tilted, the liquid will naturally collected at the outlet. This mechanism is excellent in liquid discharging performance.

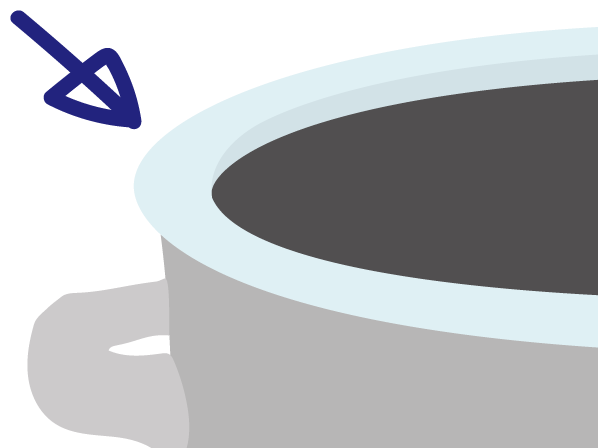

Normal Flat-Bottom Containers: Waste of liquid

Because there is a certain distance between the outlet and the bottom of the container, where liquid remains.

And the liquid waste happens due to the difficulty of discharging the entire amount of liquid.